- Industry Segments

- Product Portfolio

- About us

- Contact us

- Industry Segments

-

Product Portfolio

- Digital Prepress

- Consumables

- Digital Printing

- Digital Print Media

- Screen & Textile Printing

- Health & Safety

- Automotive

- Value Add Services

- About us

- Contact us

- Home

- Industry Segments

- Newspaper Printing

- Equipment

equipment

- Filter

- UV CtP

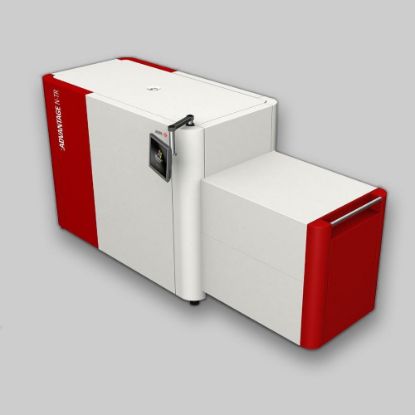

Overview Advantage N Essentials is dedicated to helping the newspaper market grow. That’s why it takes the ratio between affordability and performance to a whole new level. The new range of engines offers you the same reliability and productivity as Advantage N, only at an even more affordable price. The Essentials combine the same efficiency, user-friendliness and violet-laser imaging as Advantage N with new technology, where needed. The result? Highly reliable CtP units that offer you innovative, yet risk-free functioning. Does a more basic approach to CtP mean that you have limited options? Not with the Essentials series. Its engines support different plate-loading mechanisms, throughput speeds and levels of autonomy. You can even add optional features to adjust your engine to your personal needs.

Overview Advantage N is designed to meet your every need. Whether you are a modest local newspaper printer or the most ambitious high-volume publisher, Advantage N is the solution. That’s because this CtP platesetter family offers you a range of choices. Choose from different plate-loading mechanisms and throughput speeds (up to 400 plates per hour) to fulfill your personal wishes. Rely on violet-laser imaging, with which Advantage N units can image both conventional and chemistry-free plates. Opt for unprecedented productivity with the new Advantage N-PL or go for the affordable basics with Advantage N Essentials. Find what suits you best, yet always rest assured that you are choosing quality. Advantage N builds on the success of previous generations – Polaris and Advantage – and gives you a competitive edge.

The Gecko+ processor platform is the simple solution intended for customers who want to enjoy the processing stability delivered by Glunz & Jensen equipment, but who can do without the more advanced automated features and options that are available from the high-end processor models. The Gecko+ processor reuses technology and principles from the high-end processors, but is offered with a more basic configuration which satisfies the requirements for simple, yet consist- ent and reliable processing. The Gecko+ is built for stock in one basic config- uration and with only a few optional accessories Gecko+ 85 T/C Thermal/Conventional For traditional thermal or conventional plates with developer, wash, gum and dryer steps. Though they are similar, thermal comes with integrated cooling and brush in wash. Gecko+ P Violet Photopolymer For traditional violet photopolymer plates with pre-heat, pre- wash, developer, wash, gum and dryer steps. Very accurate hot- air preheat concept. Gecko+ 125 T/C Thermal/Conventional For traditional thermal or conventional plates with developer, wash, gum and dryer steps. The Gecko+125 is wider and more robust than the 85 model.

Throughput of up to 15 pph (720 x 576)

MicroPiezo TFP technology print-head

Maximum resolution of 2880 x 1440 dpi

Minimum spot size of 3.5 pl

High nozzle pitch of 180 dpi

Low power consumption : up to 65 W during operation

Available in 24”, 36" & 44” widths

Small footprint of 160 sq. ft.

From install to print in a jiffy

Complete service and warranty back-up from TechNova & Epson

Targeting high volume customers who are looking for superior performance in both productivity and quality, the InterPlater HDX enables fully auto- mated integration in the prepress line with both the CtP and post-processing equipment. The InterPlater HDX is the ultimate processing experience in terms of the achievable processing quality and stability, overall productivity (speed), long term reliability (capacity), flexibility in con- figuration and the level of integration with other prepress equipment. With an open processing platform, the InterPlater HDX can be reconfigured to give the absolute widest processing latitude for any application, to secure a consistent and predict- able prepress process with minimum waste and maximized uptime. In addition, we have ensured that the InterPlater HDX is easy to operate with a full graphic control panel. The InterPlater HDX is sure to fulfill your highest expectations for even the most demanding print HDX Thermal HDX Thermal 85/125/ 150/165 is the reliable thermal CtP processor that supports high-end commercial applications and integrates the latest principles of thermal plate processing. HDX NewsSpeed Dedicated for newspaper ap- plications as Fujifilm Pro-VN and Agfa N94-VCF and with the fastest processing speeds ever, HDX News- Speed offers the freedom of choice between any of the available plate manufacturers HDX Polymer HDX Polymer 85/125 includes pre-wash and a dual high capacity pre-heat oven to enable higher productivity for newspaper production at a consistent high quality. DX Polymer High Speed HDX High Speed 85 is targeted directly at high- end, heavy duty newspaper installa- tions requiring very high throughput exceeding 400 plates/hour.

The Smart’n’Easy line is the new generation community newspaper system. This innovative CTP line is designed as an integrated system with optimal interfaces to allow an easy transition to CTP for regional newspa- pers. Easy installation and operation, extremely space-saving and reliable like the big ones. Constructed for semi-commercial and newspaper production, the Smart ’n’ Easy line is offered with a work ow, manual or automatic plate- setter, processor and punch bending. All components are optically inte- grated with the same machine design without compromises of the work ow functionalities. The optional 1-in-1 or 2-in-1 con guration enables exible setup possibilities, as well as backup and double production solutions with an output of up to 100 plates per hour per platesetter. With superior quality at an excellent price/perfor- mance ratio, the Smart’n’Easy line sets new standards in this market segment.

For customers who want to enjoy the processing stability delivered by Glunz & Jensen equipment, but who can do without the more advanced automated features and options that are available from the high-end processor models - Kylin P is just the right choice!

The Kylin 85P processor reuses technology and principles from the high-end processors, but is offered with a more basic configuration which satisfies the requirements for simple, yet consistent and reliable processing.

The Kylin 85P is manufactured in Europe and complies with international safety standards, as does all our other equipment.

For violet chemfree applications Dedicated models for Agfa N94-VCF and Kodak Libra VP applications Compact, high-quality processing of low chemistry plates Raptor Chemfree incorporates innovative full featured processing in a compact, space saving “small footprint” application

The Raptor+ processor is the ideal processing solution for any medium segment printers. The Raptor+ processor offers many of the same features and benefits as the InterPlater HDX in a smaller footprint, targeting customers in the me- dium segment. This means that Raptor+ offers a high level of configuration flexibility and can be adapted to a wide range of applications, to better match the individual needs of the printer. It is prepared for full unattended operation and can be used in an automated prepress line, fully integrated with both CtP and post processor plate automation. Raptor+ combines reliability, flexibility and automation to meet the needs of any customer in the medium segment. Customers looking for high productivity or high production volume, should consider the Inter- Plater HDX. Raptor+ Thermal For traditional thermal plates with developer, wash, gum and dryer steps. Available in two widths, 68 and 85 cm. Raptor+ Polymer For violet photopolymer plates with pre-heat, pre-wash, developer, wash, gum and dryer steps. Very accurate hot-air preheat concept. Easily converted for violet chemfree technology. Raptor+ Chemfree For violet chemfree appli- cations. Dedicated mod- els for Fuji Pro-V and Agfa N92-VCF applications. Alternatively, use the traditional photopolymer processor with appropri- ate modification kit.

The Raptor+ processor is the ideal processing solution for any medium segment printers. The Raptor+ processor offers many of the same features and benefits as the InterPlater HDX in a smaller footprint, targeting customers in the me- dium segment. This means that Raptor+ offers a high level of configuration flexibility and can be adapted to a wide range of applications, to better match the individual needs of the printer. It is prepared for full unattended operation and can be used in an automated prepress line, fully integrated with both CtP and post processor plate automation. Raptor+ combines reliability, flexibility and automation to meet the needs of any customer in the medium segment. Customers looking for high productivity or high production volume, should consider the Inter- Plater HDX. Raptor+ Thermal For traditional thermal plates with developer, wash, gum and dryer steps. Available in two widths, 68 and 85 cm. Raptor+ Polymer For violet photopolymer plates with pre-heat, pre-wash, developer, wash, gum and dryer steps. Very accurate hot-air preheat concept. Easily converted for violet chemfree technology. Raptor+ Chemfree For violet chemfree appli- cations. Dedicated mod- els for Fuji Pro-V and Agfa N92-VCF applications. Alternatively, use the traditional photopolymer processor with appropri- ate modification kit.

TechNova is one of the world’s leading suppliers of Total Imaging Solutions for the Graphic Communications industry. Since 1971, TechNova has introduced several new breakthrough technologies that have transformed the imaging processes in various industries.

TechNova offers complete integrated solutions that include consumables, systems, software solutions and services for the print, publishing, packaging, textile, engineering, signage and photo industries. We are also the pioneers of the "Go Green" revolution in the Indian Printing Industry. Our mission is to continuously improve all our business processes and productivity to achieve a level of excellence that is vastly superior to all others in the industry.

Read more...Connect With Us

-

TechNova Imaging Systems (P) Limited Laxmi Mills Estate, Off Dr. E. Moses Road, Mahalaxmi, Mumbai 400 011,

Maharashtra, India -

1800 267 7474 (Toll-free India)

-